THE ECONOMY IS MOVING FROM THE INDUSTRIAL REVOLUTION TO GLOBALISATION

Exclusive interview with Mr. Anant Srivastava, Director of the Home Textile Exporter Welfare Association (HEWA)

Covid 19 changes the export industry

Covid 19 has positively changed the export industry completely. It is a boon for exporters as the entire process of export is now digitalised. Digitisation was supported by the government, financial institutions, and logistics. The documentation process is now scanned and submitted to the bank, logistics, and buyers. Buyers’ quality checking and inspection is also done through Google Meet and Zoom, where they check random samples and approve the entire consignment. In this way, buyers are saving time and reducing their dependence on the middle man quality checker. Banks are also taking scanned documents. Digitisation incorporates ease of doing business in every sense.

How Digitisation simplified the lives of textile manufacturers

Digitisation is adopted in every sphere of life today, from social networking to business promotion. For exporters, the process is further simplified through Digitisation. The entire process is now digital paperless work, which is easier for buyers as well as suppliers. A click of a button gets confirmation, approvals for samples, order quality checking, document processing, payment process, etc. The entire supply chain, from collection of raw materials to delivery and reaching the customer warehouse, is digitalised. The entire supply chain can be checked and measured. Digitalisation makes the process fast, smooth and transparent. The economy is moving from the Industrial Revolution to Globalisation to Industry 4.0, i.e., Digitalisation. It is a new revolution for industry development.

Innovative designs, weaves, and prints are capturing this segment. How does it help to achieve a minimum cost?

Designs , weaves , making prints involves textile designer who understand the process of making designs and implementing in the required machinery. Digital design definitely made process fast, smooth, every day we can make some new designs with help of software and trained designer. This is saving cost in terms of time consumption of making new designs by designers, Changes of designs are faster, it can be immediately implemented in the machine set up so it is saving time and cost both at minimum level with maximum output and productivity.

Testing of washing durability and stability to improve fabric

Home furnishing and textiles have a longer life span than apparel. This category looks for comfort at the same time. It should be visually aesthetic and stimulating to the mind. Testing of fabrics is easier than earlier as there is more automation in testing machine equipment, and test results are faster with e-communication and digital reports. Digital reports get faster value chain processes. The entire process of fabric development is done by automated machine technology. From the click of a button, the entire process can be controlled and measured. This is really a revolution, as quality checking is the most important parameter for exporters. Buyers need transparency in quality measures. Through Digitisation, everything is possible with the click of a button rather than waiting for a courier company.

Supply Chain Management

Product delivery and inventory management are key aspects of product supply chain management and production control. Earlier, for stock management, everything needed to be counted, how many items sold etc. Now everything is managed by retailers and communicated to the manufacturer/supplier, so it benefits the manufacturer/supplier to know which products are moving faster than others, as well as control inventory. If some products are not moving or slowly moving, they need to be controlled in production, or wherever they can be transferred to that store/region. Logistically, production control in all aspects is faster, cheaper, and gives forecasting for future development for the export and domestic markets.

Cost and Saving to company

Digitisation helps companies’ business processes run smoothly. Each company needs to take steps to digitise every process of business. Websites, social media marketing, search engine promotion, and other office management tools; ERP software or Google free products for database management and team management. Production management; advanced automated technology linked by cutting-edge technology. The HR process is completely digitised by software. If a company adopts systems, then there is less requirement for humans, and everything will be on your digital device. Monitoring is easier, and decision makers will get more productive time for more fruitful work and development than in daily routine.

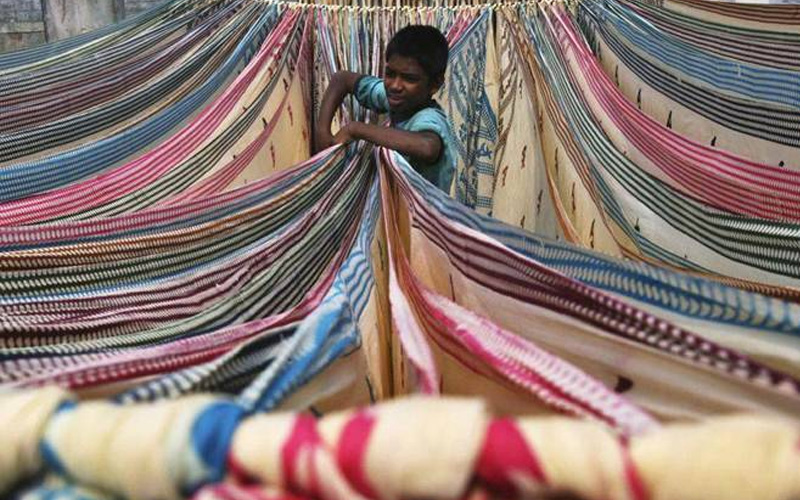

Scope: Global Market Size of the Home textile Industry. India’s Position

The global home textile market size is approximately USD 104.25 billion in 2020. The growth rate is approximately 5%-7% each year. India accounts for 7% of the global home textile market size. India is also one of the top suppliers to the world’s biggest home textile consumer market, the US. Increasing efforts in quality improvement, innovations through R&D programs, and other preferential value-added features have helped India’s home textile products become more popular in the global market. Superior quality makes companies in India a leader in the US and the UK, contributing two-thirds of their exports. Delhi, India has emerged as one of the major production and export centres for home textiles. Traditional craftsmanship, along with its distinctive appeal, is being effectively used to produce value-added home textile items.

Opportunity and Road Ahead for Indian Textile Exporters :

The world is moving toward digitisation. India has a major educated skill set that is required for the IT industry. The Indian service industry is already moving towards growth, and the digital movement of products and services puts us ahead of our neighbouring countries. India can take advantage of the talented pool with more benefits through the digital service process. With more advanced automation machines, higher productivity, innovation, variety, and high-quality raw materials, Indian textiles are becoming more competitive in the global market.